Montana’s varying weather conditions—from hot, dry summers to freezing winters—mean that flooring needs to be durable, versatile, and protective. Below, we’ve broken down some common epoxy flooring industry terms to help you navigate your concrete coating flooring options with confidence.

Q: What makes an epoxy coating a good choice for Montana garages?

A: Epoxy coatings are slow-curing, high-build coatings that are incredibly durable and form a strong bond with concrete. They are an excellent choice for use as direct-to-concrete primer coats in garages, basements and other spaces susceptible to moisture infiltration. Due to their susceptibility to UV light, they are less useful as color of topcoats for areas exposed to sunlight. However, Montana’s cold winters and snow make these coatings excellent base (“primer”) coats. When used in partner with polyaspartic topcoats, these coatings resist moisture, chemicals, UV light and heavy wear, providing long-lasting protection.

Q: What is a polyaspartic coating, and why might it be beneficial in Montana?

A: A polyaspartic coating is a “quick-cure” coating, ideal for use as a clear top coat. They provide extreme UV and chemical resistance, so unlike an epoxy, protect against UV fading and staining due to automotive fluids and “hot-tire” transfer. Furthermore, the speedy cure rate allows for a faster installation process without sacrificing durability. Unfortunately, these coatings are poor direct-to-concrete primers. However, when used in conjunction with a moisture-mitigating epoxy primer, the epoxy-polyaspartic coating systems are extremely durable. In Montana, where outdoor spaces need protection from UV exposure and staining, polyaspartics offer this in spades. Perfect for clear topcoats in garages, patios, walkways or commercial spaces.

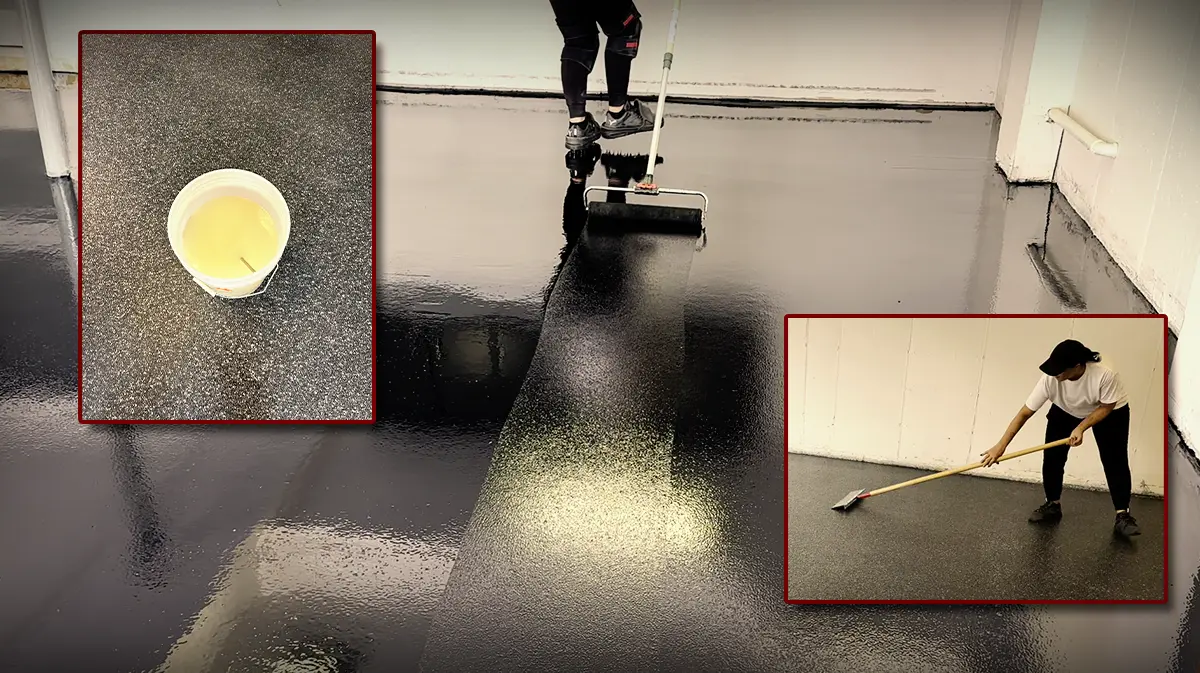

Q: How does a flake epoxy foor system add both function and beauty to my Montana garage?

A: A flake epoxy floor system involves adding decorative vinyl flakes into the epoxy primer coat to create a textured, slip-resistant surface. In Montana, where snow and ice can create slippery floors, the added traction from a flake epoxy floor system is essential. And you can to customize the look of your floor with various color options. Flake epoxy flooring provides the most durable flooring with the longest warranties.

Q: I’ve heard about concrete floor paint—how is it different from a garage floor coating?

A: Concrete floor paint is a surface-level solution that doesn’t bond to the concrete like an epoxy coating. While paint may work for cosmetic purposes, it doesn’t provide the same durability or protection as a garage floor coating, which creates a chemical bond with the concrete and is built to last in Montana’s varied climate.

Q: What is moisture mitigation, and why is it important in Montana?

A: Moisture mitigation prevents moisture vapor, which seeps up through your porous concrete floors, from becoming a problem. This is especially true in areas prone to snow melt or heavy rain, like Montana. Applying a proper moisture-mitigating epoxy primer coat direct-to-concrete ensures your garage or basement floor mitigates the damage moisture can cause over the long-term.

Q: How does polyurethane contribute to long-lasting floors in Montana?

A: Polyurethane acts as a flexible coating that provides excellent protection against UV rays and impacts. They are excellent coatings for use as color or top coats for patios and walkways. However, these coatings are typically reserved for exterior installs only, as they can be odorous and fail to protect against hot-tire transfer. Hence, polyurethanes should not be used in spaces with vehicular traffic like garages.

Conclusion

Montana’s changing weather demands tough, durable flooring solutions. Whether you’re looking for epoxy flooring or a moisture-resistant basement floor, understanding these key terms will help you make an informed decision. With GarageFloorCoating.com in Montana, you can trust that your floors will withstand the elements and look great for years to come.